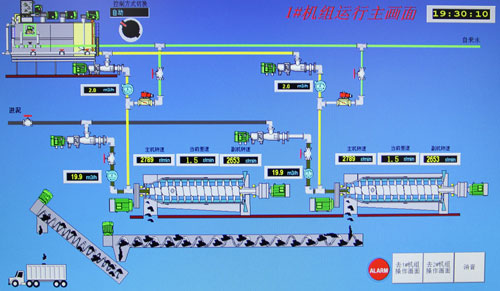

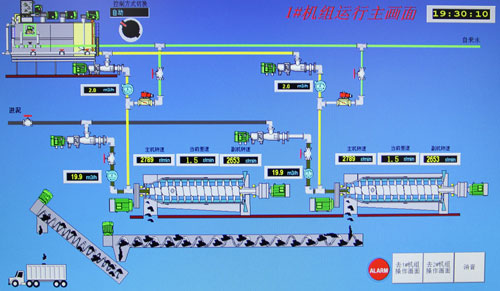

The process flow diagram of sludge dewatering equipment made by our company are as follows (mainly composed of six parts):

1, sludge feeding system: the sludge cutting machine, sludge feeding pump, electromagnetic flowmeter, valve, pipeline etc.;

2, flocculant dosing system: by PT type dry powder automatic quantitative dosing device, dilution water dosing device, pump, valve, pipeline etc.. Can realize feeding, dissolving, curing, storage, such as automatic dosing metering process, the whole process without manual operation, fully automatic operation.

3, the proportion of agent dosing system: JY type mixing barrel, electric diaphragm pump, valve, pipeline etc.. The system for oily sludge dewatering equipment (scum).

4, sludge dewatering unit (long centrifuge ratio):LW-250, LW-350, LW-430, LW-450, LW-500, LW-650, LW-720, LWnj series special mud

5, sludge delivery system (shaftless screw conveyor) design:WLS shaftless screw can effectively prevent clogging and winding of mud cake, transportation is widely used in sludge centrifugal dewatering sludge.

6, electronic control system (automatic control, PLC+ LCD screen dynamic picture display): by the horizontal screw host, feed pump, dosing pump, water pump, PLC control and related electrical control box and the LCD touch screen.

The main functions are as follows:

(1) the control system has manual control and automatic control in two conditions: in the manual control of the state, in the process of operation for various system parameters setting and tuning; in the automatic control system, parameter adjustment, flow rate and concentration of feed pump is controlled by the concentration of sludge in the pool, the dosage and dilution water fuzzy control according to the separation of liquid turbidity of the centrifuge, the control system is the automatic control process of an intelligent;

(2) with rotational speed automatic continuous measurement of centrifuge and differential speed;

(3) system with various operating parameters of condition monitoring, fault alarm, data display and print statements;

(4) through the automatic concentration detection section into mud volume, the centrifuge is always in the best working state;

(5) working with the state of the system, the alarm signal, various operation parameters and historical records sent to the host computer;

(6) current, voltage, flow rate, engine speed, speed difference, pushing torque, operation duration, parameters such as temperature monitoring and display;

(7) a dynamic picture of each operation unit display and parameter setting;

(8) through the network version of the PC configuration software, can realize the remote fault diagnosis function; the running state of animation; real-time data report; historical data search;

(9) the whole control system is composed of PLC+ LCD touch screen to implement fully automatic control, make the system in the intelligent operation of the automatic operation, is an ideal turnkey project.