Product structure diagram:

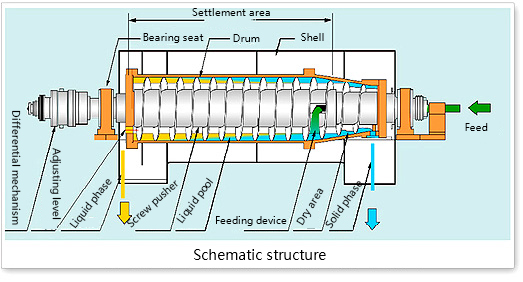

Our company for the use of specific background and requirements, the development of a variety of combinations of centrifuge and propellers: Using an AC variable frequency motor + frequency converter or an electromagnetic adjustable speed motor and driving drum and screw speed, by replacing the belt wheel to adjust the difference;

|

Solid-liquid separation |

Sludge dewatering |

Size classification |

Liquid clarification |

|

PVC resin |

Power plant sludge |

Titanium dioxide |

Soybean protein |

|

Ammonium sulfite |

Dyeing sludge |

Kaolin |

Peanut protein |

|

Barium carbonate |

Paper sludge |

Starch |

Fruit juice |

|

Strontium carbonate |

Natural gas desulfurization sludge |

Drilling mud |

Drinks |

|

Xin Defen |

Calcium carbide sludge |

Coal flotation |

Vegetable oil |

|

Barium sulfate |

Sludge Fiberboard |

Crystal flotation |

Citric acid |

|

Calcium sulfate |

Drilling mud |

Diatomite |

Waste oil purification |

|

Starch |

Two chlorine mud |

Gypsum |

Washing water purification |

|

Alcohol wastewater |

Car sludge |

Bauxite |

Orange juice |

|

PTA |

Activated sludge |

Clay |

Two chlorine mud |

|

Blood meal |

Gypsum |

Ore |

Alum sludge |

Product parameters:

|

|

Drum diameter×Length |

Drum speed |

The maximum separation factor |

The mixed liquid handling capacity |

Differential speed |

Motor |

Host weight kg |

Size |

|||

|

Host model |

Speed r/min |

The host power |

Auxiliary power |

||||||||

|

LW-250 |

φ250×963 |

3266 |

1493 |

2-5 |

20 |

Y132S-4/2 |

1440/2890 |

5.5 |

/ |

1000 |

1880×1000×635 |

|

LW-350 |

φ350×1550 |

2800 |

1536 |

4-12 |

16 |

Y160M1-2 |

2930 |

11 |

/ |

1500 |

2630×1200×755 |

|

LW-360 |

φ360×1550 |

2800 |

1580 |

4-13 |

16 |

Y160M1-2 |

2930 |

11 |

/ |

1500 |

2630×1200×755 |

|

LW-450 |

φ450×1620 |

2700 |

1837 |

6-18 |

16 |

Y180L-4 |

1470 |

22 |

/ |

2000 |

3000×1380×830 |

|

LW-500 |

φ500×1800 |

2600 |

1893 |

8-25 |

16 |

Y225S-4 |

1480 |

37 |

/ |

2000 |

3300×1410×900 |

|

LW-550 |

φ550×1980 |

2500 |

1925 |

10-30 |

16 |

Y225M-4 |

1480 |

45 |

/ |

2500 |

3500×1410×900 |